graphite electrode UHPΦ450

Model No.︰UHPΦ450

Brand Name︰Sanneng

Country of Origin︰China

Unit Price︰US $ 3050 / MT

Minimum Order︰20 MT

Product Description

Graphite electrode is mainly applied for metallurgy industry and calcium carbide, phosphor-chemical enterprise, such as iron and steel smelting, industrial silicon, yellow phosphorous ,ferroalloy, titania slag, brown fused alumina etc submerged-arc furnace melting production.

Typical Properties of Large-size Graphite Electrode.

Diameter:600mm-1400mm

Length: 1850mm-2400mm

1600$-2050$ per ton

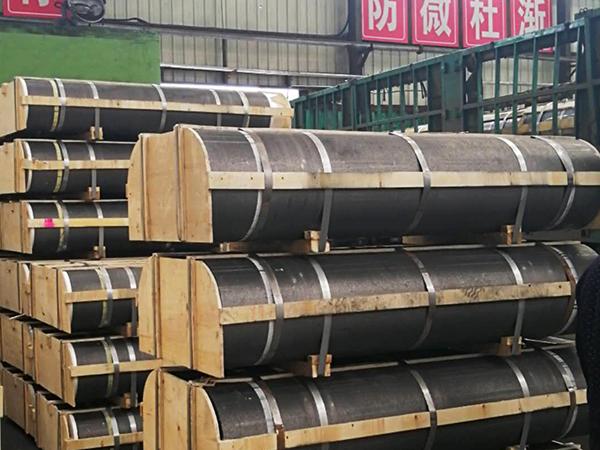

Pakage:wooden

Notice:

1. Electrodes should be stored in a clean and dry place avoiding vibration and collision. It should be dried before use .

2. When connecting the nipples, the user should clean the hole with compressed air and then screw the nipple into it carefully without damaging the threads.

3. Before the electrodes are connected, cleaning the electrode tip by the compressed air when the two electrodes are 20-30mm away.

4. When the electrodes are connected by the wrenches, it should be fully tightened to the specified location that the gap between the two electrodes is less than 0.05mm.

5. To avoid the electrode breakage, please keep away from the insulation material blocks.

6. To avoid the electrode breakage, place the aniseed block on the lower part and set the small block on the upper part.

Advantages about the Graphite Electrode :

The graphite electrode costs less electric energy and saves production cost, energy and the electricity consumption in per unit of steel-making.

Due to the fewer changing times of the graphite electrode, so it reduces the labor quantity, the risk coefficient of the operator and improves the production efficiency .

The graphite electrode is a kind of low consumption and low pollution product which has very important social significance in energy saving and environmental protection nowadays.

Notice:

1. Electrodes should be stored in a clean and dry place avoiding vibration and collision. It should be dried before use .

2. When connecting the nipples, the user should clean the hole with compressed air and then screw the nipple into it carefully without damaging the threads.

3. Before the electrodes are connected, cleaning the electrode tip by the compressed air when the two electrodes are 20-30mm away.

4. When the electrodes are connected by the wrenches, it should be fully tightened to the specified location that the gap between the two electrodes is less than 0.05mm.

5. To avoid the electrode breakage, please keep away from the insulation material blocks.

6. To avoid the electrode breakage, place the aniseed block on the lower part and set the small block on the upper part.

Our main products: we specially produce large-size graphite electrode and large-size carbon electrode, including Regular power graphite electrode(RP), High power graphite electrode(HP), ultra high power graphite electrode(UHP), high density impregnated graphite electrode, burner square graphite electrode, Calcined Petroleum Coke and various kinds and sizes carbon products. Our company owned the first class production equipment and outstanding management level, also we have strong technical force and advance tested equipment. We passed the ISO9001-2000 quality certification in 2006 and with annual production ability at 50000 tons.Typical Properties of Large-size Graphite Electrode

SPECIFICATION

Table 1: Technical Specification of UHP Graphite Electrode

|

Dia. |

Resistance |

Density |

FlexureStrength |

ElasticModulus |

AshContent |

CTE |

CurrentLoad |

CurrentDensity |

|

(inch) |

(≤,µΩ·m) |

(≥,g/cm3) |

(≥,MPa) |

(≤,GPa) |

(≤,%) |

(100°C–600°C) |

(A) |

(A/cm2) |

|

|

|

|

|

|

|

(≤,10-6/°C) |

|

|

|

10 |

5.2 |

1.67 |

10.5 |

14 |

0.3 |

1.5 |

8100–12200 |

20–30 |

|

12 |

5.2 |

1.70 |

10.5 |

14 |

0.3 |

1.5 |

15000–22000 |

20–30 |

|

14 |

5.2 |

1.70 |

10.5 |

14 |

0.3 |

1.5 |

20000–30000 |

20–30 |

|

16 |

5.2 |

1.70 |

10.5 |

14 |

0.3 |

1.5 |

25000–40000 |

19–30 |

|

18 |

5.2 |

1.70 |

10.5 |

14 |

0.3 |

1.5 |

32000–45000 |

19–27 |

|

20 |

5.2 |

1.70 |

11 |

14 |

0.3 |

1.4 |

38000–55000 |

18–27 |

|

22 |

5.2 |

1.72 |

11 |

14 |

0.3 |

1.4 |

42000–66000 |

17–26 |

|

24 |

4.8 |

1.72 |

11 |

14 |

0.3 |

1.4 |

49000–76000 |

17–26 |

Table 2: Graphite Electrode Size & Tolerance

|

Diameter(mm) |

Length(mm) |

||||||

|

NominalDiameter |

ActualDiameter |

NominalLength |

Tolerance |

ShortLength |

|||

|

(inch) |

(mm) |

(max.) |

(min.) |

(roughspot) |

|||

|

10 |

250 |

256 |

251 |

248 |

1600/1800 |

±100 |

-275 |

|

12 |

300 |

307 |

302 |

299 |

1600/1800 |

||

|

14 |

350 |

357 |

352 |

349 |

1600/1800 |

||

|

16 |

400 |

409 |

403 |

400 |

1600/1800/2000/2200 |

||

|

18 |

450 |

460 |

454 |

451 |

1600/1800/2000/2200 |

||

|

20 |

500 |

511 |

505 |

502 |

1800/2000/2200/2400 |

||

|

22 |

550 |

562 |

556 |

553 |

1800/2000/2200/2400 |

||

|

24 |

600 |

613 |

607 |

604 |

2000/2200/2400/2700 |

||

Payment Terms︰ TT/LC/Negotiate

Product Image